Automatic Optical Inspection (AOI) machines use multiple advanced visual methods to identify manufacturing defects on PCBs.

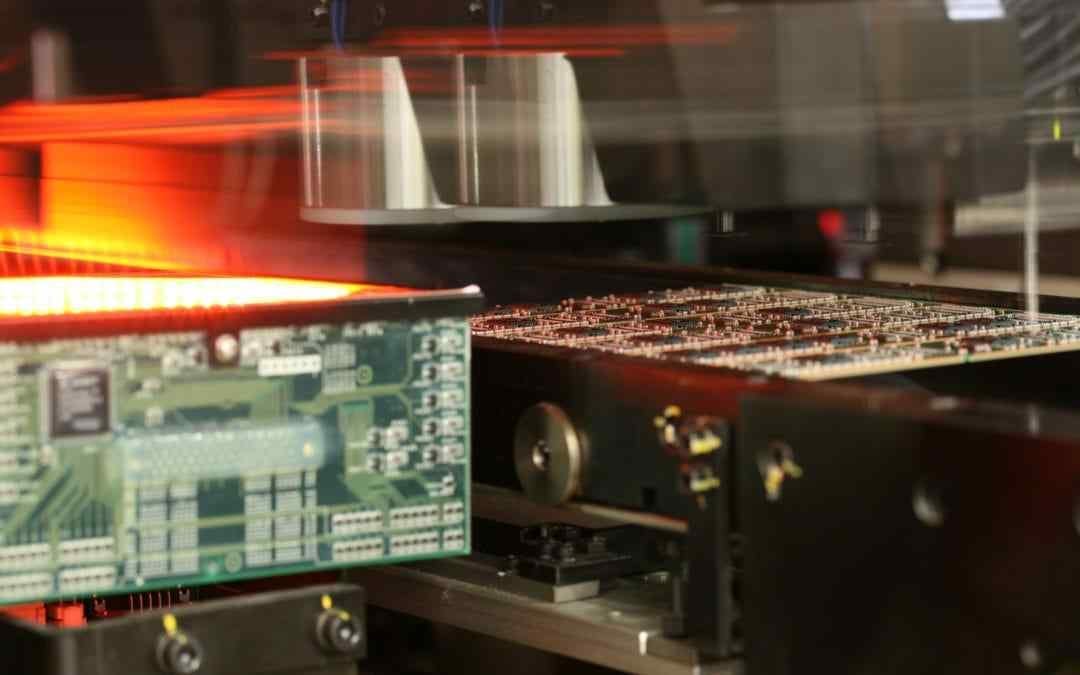

At Aurora Circuits, we have acquired multiple state-of-the-art AOI machines to scan for all types of defects to not only minimize but completely identify and eliminate PCB defects in even the most integral and complex design.

The following are important techniques used to analyze boards for various defects at Aurora Circuits:

Pattern Matching: The AOI system uses this technique to store the information on both perfect and faulty images.

Template Matching: The Automated Optical Inspection machine uses a small template that is applied to a large inspection image through a sliding template window. Then, normalized cross-correlation (NCC) is calculated between the template and inspection image.

Statistical Pattern Matching: This method is similar to the above-mentioned methods, with the only difference that it uses statistical data to address the problems. It analyzes the perfection of the image by matching the obtained images with hundreds of stored data. It is designed to accommodate minor imperfections.

AOI Benefits:

Multiple Inspection Objects – AOI test works perfectly for bare PCB inspection. Defects are checked such as shorts, solder mask openings, spacing, trace width, pad size and area, and even contamination.

Flexibility – Automated Optical Inspection can be arranged in any stage of manufacturing. To increase inspection efficiency and reduce the corresponding costs, Aurora Circuits generally tests at a variety of stages based on the board design and specifications. The flexibility attribute of AOI leads to a reduction of cost since it is an in-process test and as soon as issues are discovered, manufacturing or assembly parameters can be instantly modified.

Enhanced Inspection Speed – Hand inspection of our custom PCB is still mandatory in our facility before any and all products leave our building. Although this practice is required, our state-of-the-art Automatic optical inspection machine can cut down on hours of rework and potential human error. AOI testing run on our parts, in several stages of manufacturing, saves Aurora on costly mistakes and catches even the most minor of defects. This keeps our facility efficient and effective.

Inspection Consistency – AOI Machine technology reduces the likelihood of inconsistent visual inspection. When using machines such as these, the images are in the same position every time a panel is run through the machine. The camera will catch any imperfections using both pattern matching and template matching at the same time. Although our final inspection team is composed of highly trained professionals, many times defects on PCBs can be so small, they are invisible to the human eye.

The last keynote to mention is the importance of AOI machining maintenance. AOI systems can be extremely beneficial to a company if they are programmed correctly. In order for the machine to be truly beneficial, it must be run by competent handlers and trained professionals. Ensuring your manufacturer follows specific guidelines and training requirements can help ensure quality products, efficient lead times, and cost-cutting benefits. Aurora Circuits is not only ISO 9001 certified, but ITAR registered as well. These certifications are a proven indication of our commitment to continuous quality management and improvement.

For more information about Aurora Circuits capabilities, please visit our website at

www.auroracircuits.com/soultions.

You may also contact us directly at contact@auroracircuits.com or via phone (630)978-3830.