AURORA CIRCUITS BLOG – Updates on PCB Manufacturing and Assembly

It’s The Little Things

There are many ways to not only save money but time as well. If you take the time to examine everything we do when it comes to providing our customers with better products and services you will always find a way to save time and yes sometimes, most of the time, money....

Aurora Circuits on Track for AS 9100 Certification

Aurora Circuits on Track for AS 9100 Certification Aurora Il: Dr. Chris Kalmus, Owner and President of Aurora Circuit announced that his company has company is in the final stages of acquiring their AS 9100 Certification, and expects to be fully certified in early...

Watch those Revs! And save time and money!

One of the easiest mistakes for a PCB fab shop to make is building a board to the wrong revision. Now to some this might not seem that simple a mistake to make but it is and most of the time the reason is that the rev is not properly indicated by the customer.I think...

Planning Your PCB Design: The First Steps

There will never be a time that technology stops evolving. So why do we stop evolving our planning processes when it comes to design and innovation. Getting caught in the step-by-step routine when it comes to design can be the biggest downfall for innovation....

IMM Silver

In the never-ending search for the best possible surface finish on printed circuit boards, there is quite a bit to be considered. Circuit density (line width, line space and SMT pitch), solderability, surface flatness (for SMT applications), and shelf life to name a...

Prototyping, Quick Turns and Embracing New Technology: Our Tools for Survival

The domestic PCB industry has been fractured into two camps within the last ten to fifteen years: quick turn prototyping vs full production shops. It’s been continuously relayed to me that you can never be everything to everyone, so choose your path and stick to...

Going Fixtureless – A Prototype’s Dream

Manufacturing PCBs can be a tricky business, to say the least. When it comes to accurately testing boards, it is crucial to ensure that your manufacturer is using cutting-edge technology. Flying Probe Tests, otherwise known as fixtureless in-circuit tests (FICT) are...

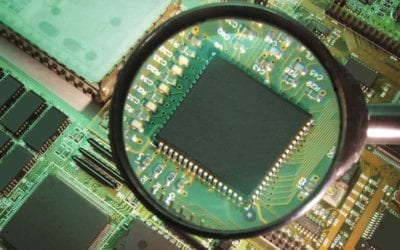

Automatic Optical Inspection (AOI)

Automatic Optical Inspection (AOI) machines use multiple advanced visual methods to identify manufacturing defects on PCBs. At Aurora Circuits, we have acquired multiple state-of-the-art AOI machines to scan for all types of defects to not only minimize but completely...

Press Release: Aurora Circuits Achieves ISO 2015 Registration

Aurora Circuits announced today that Aurora Circuits has successfully achieved their ISO 2015 Registration.

Press Release: Aurora Circuits Acquires a state of the art 30µ AOI Machine

Aurora Circuits announced today that Aurora Circuits has purchased and installed a brand new, state of the art AOI Machine.

PCB Manufacturers in the Electronic Vehicle Game

The Growth of Electric Vehicles The automotive industry's heavy-hitters are transforming their businesses and placing millions of R&D dollars into the future. What is the future you ask? You guessed correctly, electric vehicles (EV). Year over year we have...

Choosing The Right PCB Manufacturer

When it comes down to it, big problems generally start with the small stuff. The things that are often overlooked because of their seemingly small role they play in the big picture. Well, we would argue that the same goes for our industry.

PCB Fun Facts

Whether you are an industry expert or are completely new to the PCB realm, there’s a significant chance you’re missing some of the most basic fun facts!

7 Deadly Sins: PCB Manufacturability

When it comes right down to it, design flaws are built into the DNA of an end product. Ensuring that your PCBs are designed with the most effective manufacturability can not only make you more money, but it will save you time, stress, and anxiety. Unfortunately, there...

Let’s Put Our Chips on the Table

As we slowly emerge from the shock of COVID-19 and realize that this will remain in the fabric of our lives for the foreseeable future, there have been recent developments and actions from the highest level of government to bolster our economy and protect national...

Press Release: Free PCBs for Ventilators

Aurora Circuits announced early today that Aurora Circuits will produce printed circuit boards for ventilator manufacturers at no cost to speed the manufacture of ventilators.

Working for You

As we all wonder when we will get back to “business as usual,” it appears that this way of life will be with us for a while. At Aurora Circuits we are doing everything we can to service our customers while keeping our own teammates safe as possible through these...

Risky Business

We all try to mitigate risk every day in a plethora of our mundane tasks, even if it’s done sub-consciously. These instinctual responses to stimuli are ingrained into us as we develop from infants into full grown functioning adults. We all calculate risk...

RECENT NEWSLETTERS

Newsletter: April 2022

The weather in Chicagoland this month has been challenging (snow one day, high 60’s the next) and we…

Newsletter: September 2020

The Spring and Summer season was a busy one for Aurora Circuits. Although the manufacturing industry saw a downturn in bookings and production during Q2…

Newsletter: August 2020

News and insights from Aurora Circuits: Ultra-heavy Copper PCB Webinar replay; the RAM Act (HR 7594); the PCB industry in this volatile market

Newsletter: July 2020

We’re on a roll! Life as we know it has seemingly eased back into its normal routine (for the most part), and Aurora Circuits is seeing…

Newsletter: June 2020

Aurora is heating up and we’re not just talking about the June weather! Over the course of the last two months we have successfully…

Newsletter: March 2020

Customers who for whatever reason want their boards built here in the U.S. scout around and find PCB fabricators that meet…

Newsletter: February 2020

News and insights from Aurora Circuits: How buy local applies to high-tech and a sneak peek interview from iConnect007

Want the latest news delivered to your inbox? Sign up for our newsletter.

FEATURED CIRCUIT BOARD STORY

US Car Manufacturer Sitting Pretty With 67% Cost Savings

By reengineering this auto manufacturer’s PCB, the cost dropped to 33% of the original amount, saving over $375,000.

In late 2015, Aurora received an opportunity to quote a LED vanity mirror for a major, fully electric car manufacturer circuit board. The initial design was a plated-through-hole version that was fairly sophisticated for the application. The Manufacturer also required a production commencement in 60 days to prevent a shutdown of the production line.

The engineering team at Aurora Circuits suggested, after reviewing the manufacturer’s original design, that a redesign to a single-sided board would drastically save turnaround time and expense when starting production. The original design would sell for $2.25 each and require two separate printed circuit boards per vehicle. This particular part was reengineered into a single-sided, common version for less than $0.90 each, thus saving $2.70 per vehicle. When applying this to the production volume, Aurora Circuits is saving the manufacturer over $375,000 on a model year basis.

Also, to prevent any production line start up issues, Aurora Circuits built a small quantity of the plated through hole version until the single-sided version was fully tested and in full production.

Could your costs use a makeover? Let's talk.