What’s Happening at Aurora Circuits.

Carbon Printed PCBs: Aurora Circuits

Aurora Circuits is one of the few PCB fabricators in the US that has the ability to manufacture carbon printed PCBs. Carbon PCBs represent an innovative advancement in the field of electronics. Unlike traditional PCBs that rely on copper for their circuitry, carbon PCBs utilize carbon-based materials for conductivity. This unique approach offers several distinct advantages.

Firstly, carbon PCBs exhibit excellent heat dissipation properties, making them ideal for high-power applications. The carbon-based materials can effectively transfer heat away from sensitive components, reducing the risk of overheating and improving overall system reliability. Secondly, carbon PCBs are highly resistant to environmental factors such as moisture and corrosion. This resilience makes them well-suited for applications in harsh or challenging environments where traditional copper-based PCBs may degrade or fail. Additionally, carbon PCBs offer enhanced flexibility and lightweight characteristics, allowing for the creation of more compact and portable electronic devices. This flexibility opens up new possibilities for designing wearable technology, flexible displays, and other innovative products.

These unique PCBs present an exciting alternative to traditional copper-based circuit boards. Their excellent heat dissipation, environmental resistance, and flexibility make them a promising choice for future electronic applications, pushing the boundaries of technological advancement.

If you have a carbon PCB design or are thinking of launching a new project that may require carbon expertise, please do not hesitate to reach out to us at contact@auroracircuits.com.

IPC Economic Update

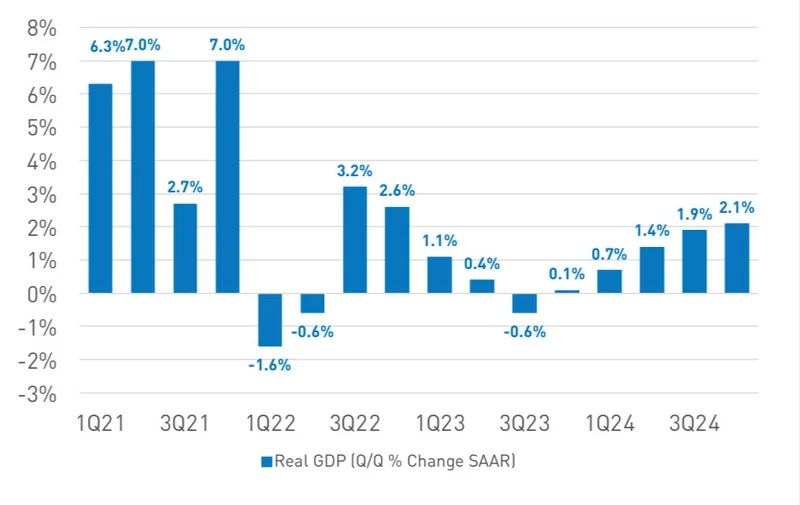

The IPC recently released its May Economic Update and the continued balancing act between economic recession and plodding growth remains in place. The artificial economic shutdowns in 2020 and 2021 make this current economic environment so difficult to understand, let alone predict for economists and pundits alike. The current job market in Europe and the US remains strong despite the consistent talk of recession the last 18 months; however, the crushing hand of inflation remains strong as wages continue to increase across the board. Inflation is the economic public enemy #1 and the FED will continue to increase rates to release these pressures.

Despite the current economic and geopolitical climate, economists are predicting a 2024 rebound and, as posed in the graphic below, a somewhat healthy close to Q4 2024. It is still difficult to determine if inflation will be in check at the stable 2% figure by the end of next year, creating an uncertain environment that we will have to muddle through for another 18 months.

Image shared from https://emails.ipc.org/links/0523-ipc-Report.pdf

A lot has changed over the past 70 years, but what hasn’t changed is Aurora Circuits dedication to remaining 100% American Made. With over 70 years of knowledge and experience to make your project a reality, we stand by our commitment to manufacture the highest quality products founded on expertise and innovation