What’s Happening at Aurora Circuits

The Latest Blog

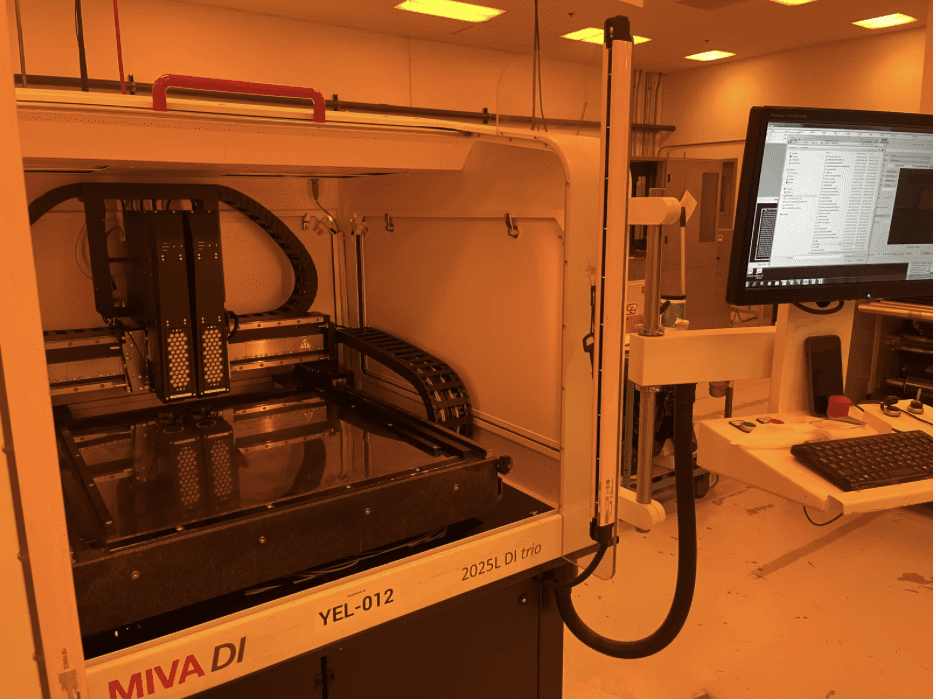

We recently authored a blog post on down cavity packaging that properly spells out the benefits of this new package that is all the rage. Embedding devices into substrates, while ensuring that the thermal controls are in place, is an emerging technology that we are well suited for based on our experience with heavy copper, milling and drilling. In furtherance of this Aurora Circuits capability set, a snapshot from the aforementioned blog post:

Aurora Circuits’ thermal dissipation and advanced interconnect technologies (active thermal cavity and or our 380 w/K thermal pads) are at the forefront in providing solutions to meet the major challenges of heat dissipation for embedded high power and high power-density SiC MOSFET packages, as well as GaN based devices. From a temperature stability, dielectric breakdown strength, thermo-mechanical performance points of view, there are ideal PCB materials for embedded SiC MOSFET / GaN module packages, of which are centric to Aurora Circuits extensive material portfolio.

We have committed the time and resources to remain on the cutting edge of the new technology. In the meantime, if your packaging team is looking for a collaborative, US based partner, please reach out to us at contact@auroracircuits.com.

Policy Updates

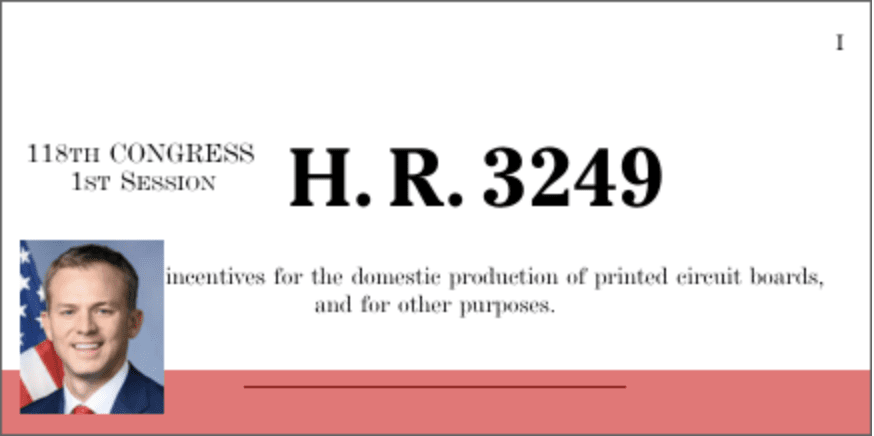

With the passage of the well-known CHIPs Act last year, many Americans have become well versed in the terms “semiconductor”, “fab”, and “wafer”, whereas a few years ago, these terms and concepts were foreign to many and the importance unknown to most. The government shutdowns in 2020 and beyond created an awakening of sorts across the globe due to supply shortages that affected many industries. Consumers, producers, politicians and economists can all agree that a level of self-sufficiency, a manufacturing reboot, is necessary to protect our national economic security and global standing. While the CHIPs Act is being slowly rolled out (funding), there is another critical piece of legislation that was introduced in May, “The Protecting Circuit Boards and Substrates Act”, which intends to boost domestic PCB production, education and research. The term “Chips Don’t Float” gets bandied about in the PCB circles and the point shouldn’t be denied. Without a healthy PCB and complete microelectronics domestic supply chain, the billions of investment in chip fabs will be largely useless if the entire domestic ecosystem is underdeveloped. Please click here to read the Bill and make sure you follow Printed Circuit Board Association of America (PCBAA), IPC and U.S. Partnership for Assured Electronics (USPAE) for updates and opportunities to get involved.

A lot has changed over the past 70 years, but what hasn’t changed is Aurora Circuits dedication to remaining 100% American Made. With over 70 years of knowledge and experience to make your project a reality, we stand by our commitment to manufacture the highest quality products founded on expertise and innovation