What’s Happening at Aurora Circuits:

The Advantages of IMS PCBs

We just released a new blog outlining the benefits of using IMS materials when constructing PCBs. The cost differential on many of the materials has gotten closer than ever when looking at FR4 type materials. The performance of IMS materials certainly bears a closer look with this in mind. Please take a look at this article snippet and to view the entire article, visit here:

1. Thermal Efficiency:

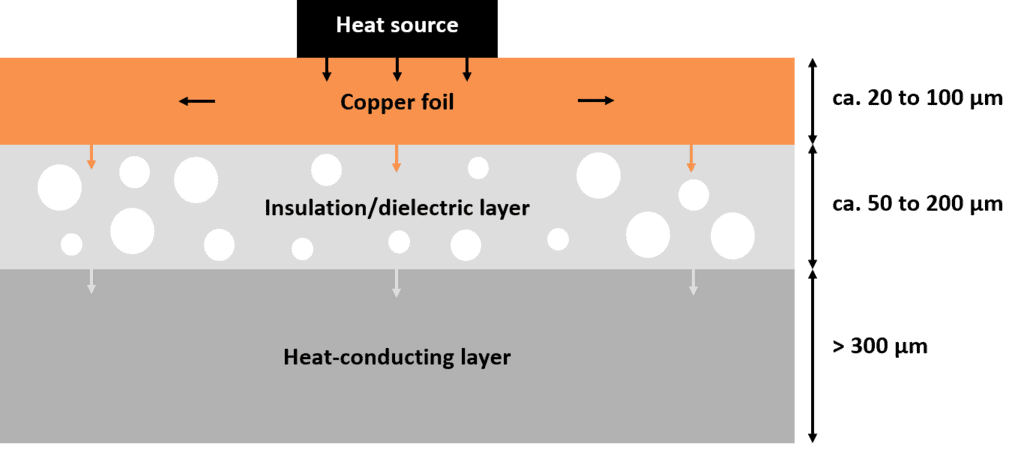

One of the standout features of IMS is its exceptional thermal conductivity. By combining a metal base, often aluminum or copper, with a dielectric layer, IMS provides an efficient pathway for heat dissipation. This characteristic is particularly crucial in high-power applications where managing heat is a constant challenge. The result is electronic devices that can maintain optimal operating temperatures, ensuring longevity and reliability.

2. Enhanced Power Density:

The thermal efficiency of IMS directly contributes to increased power density in electronic devices. As components become smaller and more powerful, the need for effective heat management becomes paramount. IMS allows for the placement of components in close proximity without compromising performance, enabling the design of compact yet powerful electronic systems.

3. Improved Reliability:

Heat is a major factor influencing the reliability of electronic components. IMS, with its ability to dissipate heat efficiently, contributes to the overall reliability of PCBs. By keeping temperatures in check, IMS helps prevent thermal stress on components, reducing the likelihood of premature failure. This is particularly important in applications where continuous and reliable operation is critical.

2024 Economic Outlook

Using “The Conference Board” as our economic guide for 2024, it looks like there may be some rough seas ahead:

We anticipate a tepid start to 2024. While the prospects for a soft landing have risen we continue to believe that volatility awaits the US economy in this year. We forecast two quarters of slightly negative GDP growth in Q2 and Q3 2024 that will be broadly felt across the economy. However, late 2024 and 2025 should usher in a period of lower volatility and greater predictability. Inflation and interest rates should normalize and GDP growth should converge to potential at just under 2 percent.*

What does this mean in a more narrow scope, specifically PCBs and microelectronics? As many of the microelectronics produced around the world go into consumer products, there may be a shift on spending that influences demand across all product types and industries. Furthermore:

Real disposable personal income growth struggled to outpace real consumer spending for much of H2 2023, pandemic savings are dwindling, and household debt is rising (along with delinquencies). Additionally, the growth in ‘buy now, pay later’ plans may also weigh on future spending as bills come due. Thus, we forecast that overall consumer spending growth will slow in Q1 2024 and then contract in Q2 and Q3 2024.*

This does not bode well for our industry, as it appears that only the defense markets may be spared from a decrease in demand during this upcoming contraction. We have mentioned in previous newsletters, blogs and posts that this economic volatility does not mirror past recessionary periods due to the external causes. The forced economic shutdowns across the globe instantly disrupted the delicate supply web that was in place, unknowingly causing years of supply chain issues, high inflation and reduced competition across many sectors. Unlike many recessions, the Conference Board did note the “labor market tightness has been remarkably persistent in 2023, but recent data show some moderation. While this should continue over the coming quarters, we do not expect labor markets to unravel (as was the case in previous recessions).”* They do mention that the Baby Boomers retiring at an accelerated clip will cushion the blow for job seekers; however, this seems to simplistic of theory. The artificial nature of the growth/contraction cycle may lead to more surprises in this component of the economic picture.

The most important pieces to the economic picture, inflation and interest rates, are set to come down to sustainable levels by Q4 2024:

On inflation, we expect to see steady progress over the coming quarters. Oil, and consequently energy prices, are falling. Meanwhile, price pressures emanating from dwellings and services continue to moderate. Notably, services demand should cool as consumer spending wanes. We expect year-over-year inflation readings to hit the Fed’s 2 percent target in Q3 2024. This expectation will trigger rate cuts starting in Q2 2024. We anticipate 25 basis point cuts at every meeting until rates fall below 3 percent in Q3 2025.

Will politicians pat themselves on the back? Official government numbers show an aggregate inflation rate from 2021-2023 of 16.9%. This, to be quite frank, is such a destructive number, the recovery may take many, many years.

*source: https://www.conference-board.org/research/us-forecast

A lot has changed over the past 70 years, but what hasn’t changed is Aurora Circuits dedication to remaining 100% American Made. With over 70 years of knowledge and experience to make your project a reality, we stand by our commitment to manufacture the highest quality products founded on expertise and innovation