What’s Happening at Aurora Circuits

Our teams have been on the road lately at events and shows, meeting the communities that we have been serving. Our leadership attended the iMAPS and IPC joint event/workshop, Onshoring Advanced Packaging and Assembly. There were discussions and panels covering governmental agencies involved in bolstering the US advanced packaging manufacturing market (SHIP/IBAS/Title III). Everyone in the government and private sectors understands that we have fallen far behind Asia and, in some instances, Europe when it comes to packaging education, technologies and investment. Industrial leaders and government entities need to work together and start closing this gap, using the current momentum to invest in next generation and current facilities–we have a long way to go and the safety and security of the US is on the clock. To learn more about this event, please visit here.

Our next stop on the conference train was The EV Charging Infrastructure Summit held in Chicago on 7/11-12. We attended to get a better viewpoint on the current EV charging space, issues related to infrastructure, markets and demand for universal charging stations. It was fascinating to see how far the charging market has come in the last few years; yet, at the same time, there is still a “wild west” vibe to the development, construction and standardization of charging stations for public and private use. We have never been one to call for regulatory bodies to insert themselves into private industry; however, to ensure a trajectory that is sustainable and manageable, it may require outside discussion and policy over the top. To learn more about the summit, visit here.

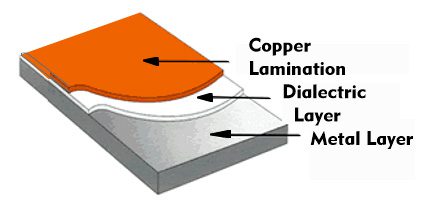

The Finer Points of Insulated Metal Substrates

Aurora Circuits has a relatively long and storied history with Insulated Metal Substrates (IMS), specifically aluminum based PCBs. Since 2003 we have been fabricating these boards for the automotive, industrial, residential and commercial lighting markets. There are many advantages to using aluminum and copper backed PCBs such as:

1. IMS materials provide excellent thermal conductivity, efficiently dissipating heat generated by power components. This feature prevents overheating and enhances the reliability and lifespan of electronic devices. The metal substrate acts as a heat sink, ensuring stable performance even under demanding conditions.

2. IMS PCBs offer enhanced mechanical strength and durability. The metal core in IMS imparts rigidity, making them less susceptible to warping or cracking during thermal cycles or mechanical stress. This robustness is particularly advantageous in applications that require high resistance to vibrations and shocks.

3. They provide superior electrical performance. The metal layer in IMS offers low impedance paths, reducing signal losses and improving the overall efficiency of the circuit. They are also capable of supporting high-frequency applications, making them ideal for power electronics and radio frequency (RF) devices.

4. Metal backed PCBs offer design flexibility. Their manufacturing processes allow for precise circuit layout and compact designs, leading to smaller and lighter electronic products. This versatility is crucial in today’s miniaturized and portable electronic devices.

5. These PCBs promote eco-friendliness. Their efficient heat dissipation reduces the need for additional cooling components, leading to energy savings and lower carbon footprints.

We have the ability to punch metal backed PCBs for full production runs, so don’t hesitate to reach out to us at contact@auroracircuits.com. Our team has the know-how and experience to realize your project to reality.

Upcoming Blog: Tariffs vs Tax Incentives

Many buyers in the PCB market understand that specific tariffs on some Chinese imported boards exist, thus making it the only current protection for domestic fabricators. Is it the best route to take, or are there other policies and programs that can further entice companies to purchase US made PCBs? We wanted to give a sneak peak on our upcoming blog post,Tariffs vs Credits: Are they both Winners, that covers this hotly debated economic policy:

When it comes to economic policy, finding the right balance between tariffs and tax incentives is crucial. Governments must consider the specific needs and challenges of their economies while avoiding protectionist measures that could escalate into harmful trade wars. In some cases, a combination of both policies might be the most effective approach. For instance, tariffs can protect vulnerable domestic industries, while tax incentives can encourage innovation and attract foreign investments.

Moreover, it is essential to regularly evaluate the effectiveness of these measures and make adjustments as needed. Economic conditions change over time, and policies that once served their purpose may become obsolete or even detrimental in the long run.

Tariffs and tax incentives are powerful economic policy tools that governments can utilize to influence trade, industries, and overall economic growth. Tariffs protect domestic industries but may lead to trade tensions and higher consumer prices. Tax incentives stimulate economic activity but come with the risk of reduced government revenue and potential favoritism. Striking the right balance between these measures is vital to promoting economic prosperity while fostering a fair and competitive global trade environment. By carefully evaluating the specific needs of their economies and regularly reassessing the impact of their policies, governments can steer their countries towards sustainable and inclusive growth.

A lot has changed over the past 70 years, but what hasn’t changed is Aurora Circuits dedication to remaining 100% American Made. With over 70 years of knowledge and experience to make your project a reality, we stand by our commitment to manufacture the highest quality products founded on expertise and innovation.